grootcbqrqig's blog

Acid resistance of acid resistant asbestos plate makes it an attractive option as a general corrosive media for flat welding flanges, particularly in the automotive manufacturing industry, where it is used for flat welding flanges due to its acid resistance. To prevent leaks on high-pressure equipment and pipelines, standard precautions should include the use of metal gaskets of the lens type or other shapes on the equipment and pipelines. These gaskets should not be made of standard rubber but should instead be made of alternative materials such as copper or aluminum alloys as well as No. 10 steel or stainless steel, depending on the application. Because of their interaction, the high-pressure gasket and sealing surface have an extremely narrow touch width (line touch), and the processing finishes of both the sealing surface and the gasket (line touch) are exceptionally good.

There are several components that must be in place in order for the flat welded flangeto be constructed correctly. These components include:the application of a gasket for sealing purposes, which is composed of the following components:It is necessary to purchase sericite powder (2–6 parts), p-diisopropyldiphenylamine (5–10 parts), and carbon black N110 in order to complete this recipe, which can be found at your local pharmacy. Benzyltriphenylphosphorus chloride in a concentration of 3–6 parts per millionThe following components: 3–6 parts ech2-to-4 parts, flame retardant 2–4 parts ech2-to-4 parts flame retardant 2–4 parts ectee 2-to-6 parts ech2-to-4 parts, p-diisopropyldiphenylamine 5–10 parts, carbon black N110 parts3 The German Langsheng EPDM 9650 is composed of 80–85 parts, of which 2–5 parts are lubricant and the remaining parts are other components. The EPDM 9650 is manufactured by Langsheng, which is a family of companies based in Germany. It is produced by Langsheng, which is a German-based family of companies that manufactures EPDM 9650 rubber. It is manufactured by Langsheng, which is a German-based family of companies that specializes in the production of EPDM 9650 rubber products. In order to create a finished product, 3 8 parts casein plastic should be combined together with 3 8 parts methyl tritylketone oxime silane and 3 5 parts Rhine wax in a ratio of 3 8 parts casein plastic to 3 5 parts Rhine wax should be utilized.

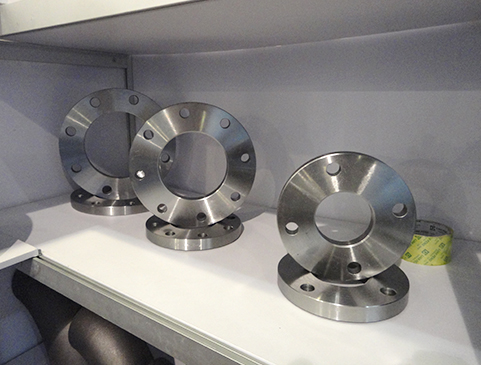

The flat welding flange, which is attached to a vessel or pipeline with the help of a fillet weld, is an example of this type of attachment. When it is used, it can be found in a variety of different situations. If you look closely, you'll notice that flange was chosen at random for your use, and that's all there is to this whole thing. During the analysis phase of the design process, knowing whether a flange is integral or loose based on its type will be beneficial to the design process. As a result, when designing the straight cylinder section and its connection to the flange ring, it is critical to consider how to make this connection as strong and secure as possible because this is where the majority of failures can occur. By their structural design, flange rings can be divided into two categories. The first category includes those that have an internal neck, and the second category includes those that do not have an internal neck. The more common type of ring is a flange ring with a neck.

We will go into greater detail about the advantages of flat weld flanges in the sections that will follow this one.

For starters, the flat welding flange welding device is simple to operate and convenient to carry around. Furthermore, positioning this device in the desired location is a simple process with this device.

Abrasive materials are used in a wide variety of industries, including metallurgy, machine tools, the chemical industry, petroleum exploration and production (including water conservation), shipping, environmental protection (including coal), agricultural machinery (including food), boiler and pressure vessel construction (among others).

It is also possible to order a flat welding flange that has a flat and smooth appearance, which is a very appealing option to take into consideration. Typically used to connect carbon steel pipe, these flanges are available in a variety of sizes to accommodate a variety of pipe diameters.

One of the functions of a flat welding flange, among others, is that it can adhere to the pipeline while also performing the pipeline sealing function during this stage, which must be completed before the pipeline can be used in its intended application.

One disadvantage of flat-welding flanges is that they are unable to be joined together with other flanges.

It is not permitted to use insufficient rigidity with the intent of causing bodily injury as a result of the insufficient rigidity.

Its purpose, as described in paragraph 2, is to make navigating potholes in the road while traveling a little bit more bearable.

They are moved around and repositioned on a regular basis in order to keep their effectiveness up to date. Because there are so many different styles of hair pieces to choose from, it can be difficult to master the attachment process for honest hair pieces. This is due to the large number of different styles that are available. We encourage you to read our blog post on how to properly style a hair vendors in china topper if you want to learn more about the subject.

It is important to consider how much coverage you require when deciding whether to wear a wig or hair extensions. If you have complete hair loss or want all-over coverage, wearing a wig is the best option; however, hair toppers are the best option for concealing thinning hair around the scalp, such as the crown and parting areas as well as at the temples. Hair extensions are the best option for concealing partial hair loss or for concealing partial hair loss in the back of the head.

However, getting things done the right way is not always as straightforward as it appears. It is possible that wigs are a more appropriate alternative to hair pieces than good hair vendors pieces alone when experiencing brazilian hair bundles loss all over your head and neck (even if you are not completely bald). Even though toppers are typically used to treat hair thinning on the scalp, they can also be used to increase the volume of the hair, which is an advantage of doing so.

Hair pieces that cover the entire head, which are available as an alternative to wigs, are a good choice for those who want complete coverage but prefer a less fussy, more temporary solution.

The use of wigs and hairpieces both has advantages and disadvantages; full wigs in particular, can make your daily routine a lot more manageable than it would be otherwise. Alternatively, if complete coverage is not required, a hair piece may be a more preferable option if you are willing to put forth the extra effort necessary to become accustomed to wearing it in the first instance.

Hairpieces may be ineffective if you are experiencing hair loss as a result of alopecia or chemotherapy treatment, for example.

It is important to keep the considerations listed above in mind when deciding whether or not wigs or hair pieces are appropriate for your needs and circumstances. Final say on which option is the best fit for you and your specific circumstances, both in terms of coverage and personal preference, is ultimately up to you.

However, while it appears to be a cost-effective way to save money on labor at the time of purchase, it almost always ends up costing significantly more money in the long run. Hytrol conveyor and pallet conveyor costs of reactive maintenance are three to nine times higher than the costs of preventive maintenance, including the additional costs of secondary equipment damage, lost production, rush shipping, and employee overtime.

According to a survey conducted by Plant Engineering in 2017, organizations that implemented preventive maintenance saw a 69% reduction in equipment downtime. Additionally, 66% of organizations were able to reduce the likelihood of failure while simultaneously increasing the operational life of the assets.

Their use enables technicians to routinely monitor Vertical Storage equipment and identify parts that are not performing properly and may need to be replaced. These replacements can then be completed during scheduled downtime. In comparison to reactive maintenance, it is estimated that this approach will save between 12% and 18% in costs while simultaneously increasing the equipment's life cycle.

If the equipment is used too frequently, a reactive approach can reduce its lifespan by up to 60% if it is used too frequently. According to safety statistics, technicians working on reactive projects are 28% more likely to be involved in an accident than those working on proactive projects because they are under intense time constraints to get the equipment back up and running. They are frequently forced to take risks or take shortcuts that they would not otherwise take if they had a proper plan in order to complete the work safely in these situations.

It has been my pleasure to work closely with customers in both the local and national markets as they investigate the possibility of moving their operations away from standard, manual picking and toward automated processes. For distribution centers to be properly automated, there are four critical steps that must be completed in order to evaluate and identify the most appropriate automation.

Cleaning, lubrication, adjustments, and minor repairs are all examples of preventive maintenance, which is the practice of performing manufacturer-recommended maintenance functions such as cleaning, lubrication, adjustments, and minor repairs on a regular basis according to a schedule established by the manufacturer.

You may not be getting the most out of your pickers because your distribution center has seen an increase in the number of SKUs and the volume of orders, or because your typical order has shifted from retail to more ecommerce sales, resulting in more requests for smaller orders. In some cases, it is possible that you are having difficulty finding enough labor to keep up with the demand for your products and meet your service level agreements. Adapting to market changes as well as shifting fulfillment operations to meet the demands of today's ecommerce customers present a variety of challenges for businesses of all sizes, large and small, around the world.

Reactive maintenance is the practice of continuing to operate a piece of equipment until it completely fails. It is defined as follows:After a failure occurs, maintenance activities are completed and the problem is resolved. Maintenance activities are not performed until after a failure occurs. Customers perform their maintenance activities in this manner, on average, according to industry estimates, with over 55% of customers doing so.

At this point, you may be considering making changes to your order fulfillment process, and you may have heard about the various types of picking automation that are available. How do you even get started, though? If your company's operations could benefit from automation, would you consider it?

Recently, the packaging industry has experienced significant growth, which coincides with the expansion of e-commerce. Online retailers and wholesalers are beginning to recognize that effective product packaging is just as important as any other aspect of their business, and they are investing in a variety of strategies to improve the efficiency of their logistics management procedures.

In today's world, finding the most cost-effective option is one of the most difficult challenges in logistics management. The majority of businesses switch from one carrier to another on a regular basis in order to maximize their packaging savings. Few, on the other hand, investigate how to redesign packaging procedures in order to make the process more cost-effective and efficient.

It will be discussed in this blog post how you can take advantage of new technologies and make small changes that will completely revamp your packaging processes while also saving you money. Things to know if you need to package something for delivery.

Understand the factors that contribute to the increase in your packaging costs.

Identifying the factors that contribute to rising packaging costs will be perhaps the most important task in this sequence of activities. These are typically redundancies and lags that drive up your costs and get in the way of a seamless, cost-effective packaging operation, among other things. It could be as simple as a few small adjustments you forgot to make or as complex as a number of factors coming together to hold you back.

According to general consensus, some of the most well-known factors that contribute to increased packaging expenses are as follows:

Design flaws in storage materials and packaging lines are widespread.

Packaging lead times that are unnecessarily long

Making payments based on the dimensions of the box, rather than the dimensions of the product

Packaging materials of poor quality that leave the possibility of damage

Failure to optimize your packaging processes is a costly mistake.

Shipping is prohibitively expensive.

Keep in mind that your overall packaging costs could increase as a result of any one of these factors, or as a result of a combination of them. Because they are all different in terms of complexity, you should take your time to figure out what is causing these price increases. Once you and your team have a clear picture of what might be going on, the next step will be to figure out how to deal with the issues and reduce your packaging costs as much as possible.

You should also be aware that some of these factors are known to lead to the development of others. For example, inefficient manufacturing and packaging models could contribute to a failure to optimize your packaging. Consequently, even though you have two factors, it is really just one of them that is causing the other. In order to effectively address these issues, you will need to take a holistic approach to packaging innovation and figure out how to reduce your costs as much as possible.

As a result of the fact that cardboard can be folded and modified more easily than other materials, please allow me to share with you some examples of Custom Chocolate Boxesboxes that will undoubtedly improve the aesthetics of your retail establishment, such as the ones displayed below:

Plastic boxes in a variety of shapes and sizes, including round and oval shapes, are available in clear plastic.

Boxes with sleeves are preferred for cake gift packaging; boxes with gable ends are preferred; and pyramid-shaped boxes are preferred for cake gift packaging, to name a few examples.

It is important that cakes are packaged in containers that are tightly sealed to prevent them from being accidentally opened. There are donut boxes with flip-top lids that hold a dozen donuts available for purchase.

The boxes were constructed with the help of pastry slices that served as templates.

To create transparent drawer-style storage containers with easy visibility through the top, a clear top is combined with a cardboard base box.

The cake boxes, which have windows and large openings on the sides, can be personalized to serve as wedding favors.

Truffle boxes can be made to order in any size or shape upon request, depending on the product.

Aside from that, it is also easier to keep the frosting and decorations on chocolate box packagingcakes and other chocolate-based products from becoming stale as a result of the large number of custom Custom Chocolate Boxesboxes that are being opened.

Resistance is a possibility that can manifest itself in a variety of ways, depending on the situation.

Make sure that the wholesale chocolate boxes you are considering meeting the requirements of the quality check specified on the edible's packaging before making a decision on whether or not to order wholesale chocolate boxesboxes. This is also true for the organization for which I would prefer to work, which possesses all of these characteristics. For example, their use of food-grade materials and FDA approval for their custom box packaging are both examples of what they do. In addition, these personalized chocolate box packagingboxes are resistant to changes in environmental conditions such as heat, moisture, and mold. It is for this reason that these modifications are made in the first place: they have the potential to degrade the freshness of products. Additional benefits include the fact that these Custom Truffle Boxes are both biodegradable and recycleable, implying that, once they have served their primary purpose and have been recycled, they will pose no threat to the environment at all.

Additional characteristics of your packaging that will contribute to the overall sweetness of your product include:

Boxes for chocolate boxespackaging will be enhanced with additional features such as windows and dividers, which will contribute to the overall improvement of their overall appearance and functionality. Adding these enhancements to your home or commercial property will undoubtedly be beneficial in terms of increasing the overall attractiveness of your home or business. I would also suggest that you include handles on your custom chocolate boxes if at all possible. I hope this helps. As a result, your customers will have an easier time transporting them, and you will use fewer plastic and polythene bags than you would have otherwise needed. As a result, the company's ability to attract new customers in the future will be significantly enhanced. Please keep in mind that clear window inductions on the top and front of the box have their own appeal for customers, and they can also assist you in reducing the amount of printing on the boxes that hold your chocolate. Opening the box reveals a presentation that is both enticing and delectable, as well as the chocolates that have been placed inside of it. As a result of this, customers will have a better understanding of the interior design and construction of the product. It is possible to prevent the delicious chunks of Chocolate Boxesfrom moving around in their containers by using dividers, which will allow them to remain firmly in their designated locations within the containers.

It is also used to create a smooth and shiny surface on the printed chocolate boxes, which helps to maintain their visual appeal while still allowing them to function properly. A type of thin silky layer that protects the product from a variety of potentially harmful factors such as moisture and sunlight when applied to customized box packaging. Polyester was used in the production of this item. . . . In addition to gloss and matte lamination, my dependable company also offers spot UV and aqueous lamination, as well as other options, such as semi-gloss AQ and other options, among others. Both gloss and matte lamination are also available in a variety of colors and finishes.

Because of its high vacuity, VIG has provided the world with excellent heat insulation, condensation resistance, and sound insulation.

1 Insulation against the heat

Regarding VIG structure, the edge is soldered, and the center is separated by supports to form a vacuum chamber. As a result of the above structure, the heat transfer coefficient in the central area of the VIG is far less than that in its edge, and when considering practice in the real world, the heat transfer in the edge is associated with the window frames. Consequently, the U value in the central area of the glass is only measured for the purpose of parameter comparability and not for any other reason.

Heat transfer through insulated glass is determined by both air heat transfer and quisure insulated glass radiation, with air heat transfer taking precedence over display cabinet door radiation in the majority of cases. The heat transfer coefficient of insulated glass is significantly higher than the coefficient of VIG from the original glass with the same emissivity on which it is based.

Table 2 shows that when the outside temperature is 25 degrees Celsius, the temperature inside the vacuum observation box stays at 60 degrees Celsius for an hour; the surface temperature of the VIG (2 # observation window) is 25.3 degrees Celsius, which is nearly consistent with the outdoor temperature. The vacuum observation box has shown better insulating ability when compared to the observation box made of other materials.

Note: R1 represents the thermal resistance of the inside display cabinet door; R2 represents the thermal resistance of the outside glass; Rradiation represents the thermal resistance of the radiation; Rsupport represents the thermal resistance of the support; Rair represents the thermal resistance of the gas residual; Rvacuum represents the thermal resistance of the VIG; Cvacuum represents the conductivity of the VIG.

Table 3 shows a comparison of the condensation performance of insulated glass and VIG, with the result being that VIG has a better anticondensation performance than insulated glass. To start condensing the VIG under the conditions of 25 degrees Celsius inside and 75% relative humidity, the temperature outside must be at least -69.5 degrees Celsius; however, with insulated glass, the critical temperature is only required to be reached at -4 degrees Celsius.

As shown in Figure 4, the acoustic insulation performance is relatively poor in the frequency range of 160-6300 Hz for frequencies less than 500 Hz. The reason for this is that the low frequency is more likely to cause the display cabinet insulated glass door to vibrate, and the sound energy is transferred from one side to the other side through the pillars.

When operating in the frequency range of 500Hz to 3150Hz, the sound insulation properties of glass are relatively good. In this case, the maximum is 42. 5dB at 1250Hz, and the minimum is 35dB. This means that the sound insulation performance of VIG is significantly better than that of laminated glass and insulated display cabinet door. For example, the sound transmission loss of 5+ 0.3V +5 VIG is only 26dB, while that of 5+9A+5 insulated display cabinet insulated glass door is only 32dB; and that of 5+0.76p +5 laminated quisure insulated glass is only 32dB.

In order to make an informed decision when purchasing a new walk-in refrigerator or freezer, a number of considerations must be made. Walk-ins can be purchased with solid walls or with the option of side glass display doors. Depending on what you intend to store in your walk-in refrigerator or freezer, you should choose the type of walk-in refrigerator or freezer that you want.

Look at how solid door construction compares to hollow glass door construction and then decide which is better for your commercial refrigeration requirements.

DOORS FOR DISPLAY MADE OF freezer glass door ARE:

If you own a retail space where customers frequently view products and remove products from the refrigerator or freezer, you may want to consider a cooler with several glass doors. It is possible to find commercial walk-in coolers with glass doors that have more than 20 display doors, which allows customers to see the refrigerated merchandise while they are shopping. For businesses where the main attraction must be kept refrigerated or frozen, glass doors are a must-have feature in the facility. For businesses such as bottle shops, convenience stores, and markets, walk-ins with display doors are an excellent choice for their customers. In the future, any business that plans to operate as a self-serve or grab-and-go operation will find that having a walk-in with display doors will be extremely beneficial for their operations. A clear and condensation-free view of your merchandise is absolutely essential, which is why choosing the appropriate glass doors is so important! The use of heated glass for your display walk-in may be necessary in certain circumstances. The Bush refrigeration company guarantees that when you purchase one of our products, you will have complete visibility into your cooler.

WALLS OF INSULATION THAT ARE COMPLETELY STONE:

If your walk-in refrigerator or freezer is intended solely for storage and is primarily used by coolers, it is unlikely that insulated glass doors will be required to maintain a consistent temperature inside the appliance. Our glass refrigerators and freezers are of the highest quality, but due to their lack of insulation, they are unable to provide the same level of protection as a solid wall walk-in cooler upright display insulated glass door or freezer. Taking into consideration the foregoing, skipping the glass doors is recommended if customers will not be in close proximity to the store and can help you save money on operating expenses.

The process of selecting the appropriate type of walk-in can be straightforward if you consider the factors listed above.

The city of Long Beach issued a temporary order on Friday, allowing businesses to temporarily raise ocean containers in their yards for storage while the massive backlog at the ports of Los Angeles and Long Beach is being worked through.

Long Beach terminals that regularly stack containers six high do not need to comply with the requirement because they do so on a regular basis. Following several weekend media reports conflating the port with the inland zone, the port has increased its Vertical Storage capacity as a result of the misinterpretation of the facts.

A change has been made to the zoning regulations for warehouses and container yards, which now allow warehouses and container yards to stack four containers instead of the two that were previously allowed. It is permissible for business owners who obtain permission from the fire department to stack a maximum of five containers on their property. In the busiest shipping and shopping seasons, which last for a total of 90 days during the busiest shipping and shopping seasons, this is applicable.

As far as aesthetics are concerned, industrial equipment has a negative impact on the appearance of surrounding neighborhoods. A change in interim rule has only an impact on those attributes of container storage that are specified in the container itself, rather than the container itself, as was the case with the previous rule.

In response to the declaration of a national emergency by California Governor Gavin Newsom earlier this month, the city manager has decided to temporarily relax the stacking and height restrictions on containerized goods.

According to the city's website, officials in Long Beach will evaluate the solution's success as well as any potential community consequences in the coming weeks, with a report to the City Council due in the first week of November.

According to the Coast Guard, a total of 79 container ships were stranded at sea on Friday while waiting for a berth at ports in Southern California, primarily as a result of Asian imports, which contributed to the situation. It has taken nearly six days for containers to be released from Southern California ports after being held there for nearly six days. Following Los Angeles, the city of Long Beach handled the highest number of containers in September, with the city of San Diego trailing closely behind in terms of the number of containers handled during the same period.

In a test conducted at one of its maritime facilities last month, the Port of Long Beach reported that the preliminary results have been encouraging so far. Despite the fact that the gate hours have been extended, only a small number of truckers have taken advantage of the additional time available to them.

The receiving of shipments from ports is being done in warehouses that are completely full, with no additional space available for receiving more shipments.

For the city of Long Beach, California's zoning regulations required a trucking company with six yards and 153 contract drivers to load containers onto chassis rather than trucks in order to comply with the city's ordinances. The company had six yards and 153 contract drivers at the time of the incident. Containers having difficulties returning to their original ports is something that occurs on a regular basis.

When leaping restrictions are lifted, thousands of chassis housing wheels will become available for use, resulting in an overall increase in the number of wheels available to play with.

Agriculture Transportation Coalition Executive Director Peter Friedmann has called for the relaxation of local zoning and land use restrictions in order to allow for increased container storage near ports, following up on a statement issued earlier this week.

As well as advocating for issues such as preferential treatment for import freight by ocean carriers and terminal fines for late collection and delivery, the AgTC is also involved in a variety of other issues and concerns.

In the opinion of Western Overseas CEO Carlo DeAtouguia, increasing the stack sizes for city businesses is nothing more than a stopgap measure. Because of an increase in the number of container stacks at Union Pacific's massive intermodal rail facility in Joliet, Illinois, customer wait times at the facility, which is located in the Chicago suburbs, have increased as a result of the facility's expansion. The massive intermodal rail facility that serves the facility is located in the Chicago suburbs.