wisepe's blog

Laser systems are so easy to use that you can start using them in no time, and are affordable, often paying for themselves in a very short period of time! Whether you choose to open a storefront business or work from home, you will find laser engraving to be a profitable way to start a new laser engraving business.

Here are some ideas for starting a business:

Wedding gifts: photo albums, etched glasses

Signage: Make custom signs out of wood and acrylic

Models: from architectural models to toys

What does it take to start a business?

A laser engraver machine can get you up and running quickly. All you need is a laser machine, your own computer and your favorite graphics software package. A laser machine works just like a printer - you can import graphics, images or text, place the artwork on top of your engraving, and it can be engraved in minutes!

Is it profitable?

As soon as you can add value to your product with custom engraving, your profits will skyrocket. We have had clients pay for their machines on their first engraving job!

What materials can I engrave and cut with a laser?

The great thing about starting a laser business is that atomstack laser systems are versatile. With one machine, you can engrave and/or cut wood, acrylic, plastic, fabric, glass and more. You are only limited by your imagination!

Today, many materials are used to make various items, souvenirs or promotional products. In this production, only innovative laser cutting can provide the highest quality processing. Of course, most of these materials, such as wood or metal, can also be processed the old-fashioned way on machines or sawmills. However, the precision with which to manufacture specific shapes and perfectly flat surfaces - can only be achieved with laser cutting. Additionally, this method of material processing reduces waste. Lasers produce the highest quality cuts—and often don't even require grinding. It is for this reason, and due to its wide application in various industries, that laser cutting is considered a very profitable business today that can bring in profits. So it's no surprise that more and more people are considering laser cutting to start a private business.

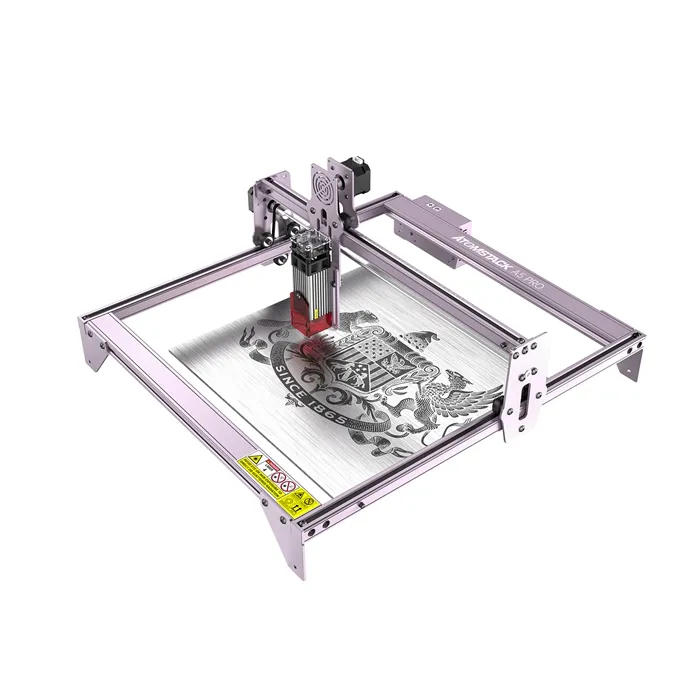

The main advantages of laser cutting are precision and the possibility to obtain irregular external shapes - but also smooth and shiny edges. Today, everything is almost completely automated - so it's no surprise that atomstack a5 m50 pro laser cutters are becoming more widely used. Thanks to advanced technology, you can download files directly from the client, or create programs according to the specific requirements of the client. The experience of most people who have been in this business has shown that a laser cutting business is a guarantee of quality for your future clients. On the other hand, modern machines offer efficiency and fast delivery.

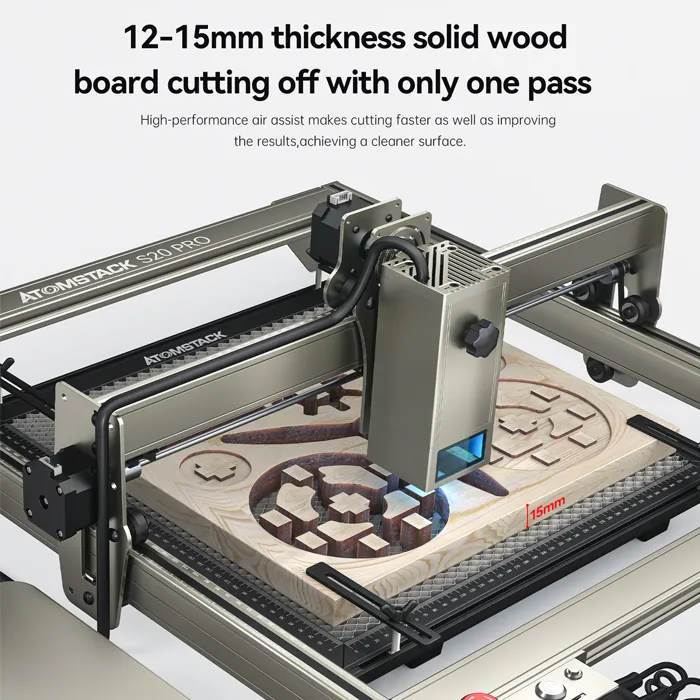

A laser cutting business can be very profitable. Of course, you have to have a plan before you start. That said, a atomstack s20 pro laser cutter can realize many of your business ideas - and if you're already thinking about it - you should know ahead of time what type of product or material you'll be focusing on in your business. So try to imagine your type of production before starting this business. Of course, in 2022, with the development of this technology - the application of laser cutting machines in entrepreneurship is becoming more and more extensive. Here are some ideas that might help you when it comes to starting a profitable laser cutting business.

It can be the most wonderful time of year, but finding the perfect gift for your loved one can be a real chore - especially if it means you have to go to the store, or you can't find what you want online Things to ask for. But as the age-old advice goes, when you give a gift, it’s the thought that counts, and when you combine that with the challenge of finding a great gift, it’s no wonder so many creative people Both tend to make Christmas presents.

In this post, we're looking for ideas to inspire your laser cutter, laser engraver to make Christmas gifts. You can use the projects we link to in whole or in part, or inspire an entirely different design - whatever you do, as long as the recipient of the gift is happy, that's all that matters!

The benefits of making a gift

The great thing about using a atomstack laser cutter for gift making is that you can make completely custom items as long as you have the right materials. So if you've spotted an idea for a friend, but it's just not the right color, shape, or texture, you can use your makerspace to craft an idea that works best for them.

While making gifts for friends and family may not be cheaper than buying presents in some cases, gift making can give you the opportunity to exercise your design skills if you already have filament or other materials available. Not only that, but it also gives you the opportunity to use up scraps etc if you already have enough on hand that might otherwise sit there for a long time - there are only so many ways to use up glitter acrylic sheets, or organically after all Glass frost and fluorescent lights!

If your goal is to make this Christmas the year you start giving sustainable gifts, then not only can you make sure you're making something that people love and use, you're also using natural materials like wood, cork, and ecological rubber.

Gift Ideas to Make for Kids

Every year you probably check out the most popular gifts and put off buying anything on those lists because they include loud and irritating toys that kids only love for 3.4 seconds before moving on to the next thing. When you make something for kids, they might head for noisy and annoying presents first. Still, there's a good chance that your handmade custom item with your laser cutter will be a visionary gift and one they'll miss for years to come.

Personalized Dollhouse or Garage

Sure, kids might really want the latest Barbie house, or that Hot Wheels toy they've seen on TV or reviewed on YouTube -- but wouldn't they love a toy that absolutely no one else in the world owns? Once upon a time, this type of project could be made out of wood and painted, and was a labor of love for a child. Today, these types of products are of course still created out of love for kids, but there are so many more options!

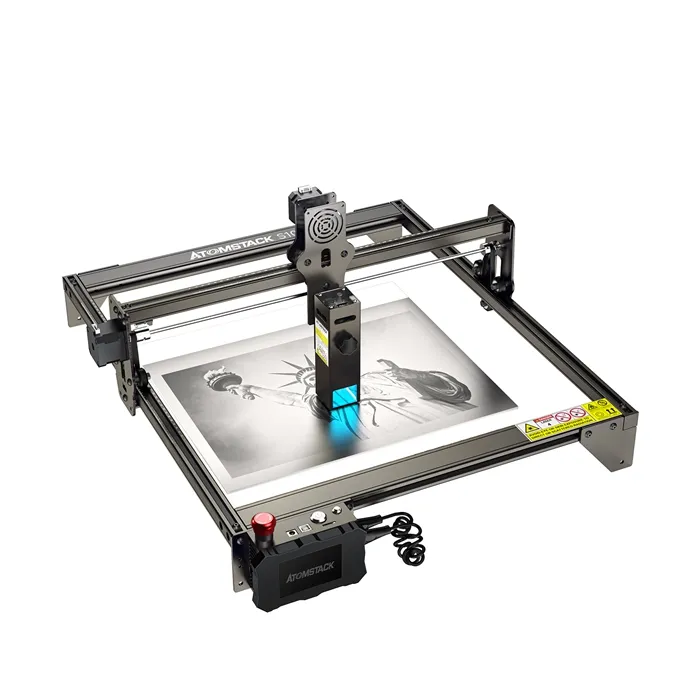

For kids who love to play tricks, this atomstack s10 pro laser-cut cabin dollhouse is great, as is this multi-storey garage -- and if the lucky recipient is an avid car fan and has access to storage space, then this laser-cut How about wall storage? Kids will love it, and as they get used to tidying up their car, so will their parents! Whether you use or design a project you create or make for the kids in your life, adding a little personal touch will make them happy and mean they'll cherish the gift long after it's received.

Christmas scene model

Being able to create their own Christmas scenes during the holidays is a great way to help kids get in the festive spirit, and they can move things around as they please – unlike in the main areas of the home! You can buy this kind of thing, but if you're an avid modeler and they're obsessed with atomstack s20 pro laser cutter, creating their own seasonal scenes means you can keep adding new pieces every year. If they really cherish it, they will likely continue to take it out year after year, even into adulthood. If you plan to add to your collection year after year, you may want to add the year each piece was made—and don't forget to keep your measurements handy so subsequent years don't look out of place.

Depending on the family's religion, you could create a nativity scene, or just a snowy town scene. There are some lovely trees in this project, and this Mandalorian manger scene with Baby Yoda might appeal to older kids. If their home doesn't have enough space to store or display lots of models, use a laser cutter to create 2D models and add magnets to the back of the models so they can sit on a magnetic board.

The prices of laser cutters and engravers have been dropping, which is why I decided to give it a try. A few days later, I received the Atomstack A5. This is a 20 W laser engraver, not a cutter, although it can cut plywood up to about four or five millimeters. Also, it's not good for engraving metal, as it seems to be able to engrave aluminum too.

The A5 comes as a kit of parts that you must assemble yourself. It's not very difficult and all the tools it needs are included in the kit. These six steps take about 30 minutes total to complete, and you'll end up with a quality, dependable component. All solid aluminum with no plastic parts (except the goggles).

Make sure the strap is tightened properly. Not too tight, not too loose, you want a smooth glide. The same goes for the guide wheels in step 5. If it's too tight, you might feel a click when you move the X axis; if it's too loose, things might start to wobble. The laser head also has a guide wheel, which may also need adjustment.

The software that controls the Atomstack A5, LaserGRBL, is free. There's also LightBurn, which isn't free, but has a limited-time fully functional free trial. Once you have mastered your router, you might want to give it a try.

The installation manual included with the kit doesn't explain how to use the engraver, nor does the Atomstack website. By the way, the LaserGRBL tool is an open source tool developed by arkypita, not related to Atomstack, which is helpful in itself, but doesn't provide real guidance either.

After connecting the A5 to my Windows 10 computer, I noticed that it requires a CH340 USB-to-serial converter driver. However, you don't have to search for it online, as it's conveniently included in LaserGRBL's Tools menu.

There is also an option to upload firmware, which is possible because the Atomstack control hardware is actually a custom Arduino running the popular open source g-code interpreter GRBL. That's great news for manufacturers and hackers, because there's nothing proprietary inside the A5.

As a first try, I repeated the plywood cutting benchmark shown in the video on the LaserGRBL website. I load the sample drawing in LaserGRBL and hit the play button. After a few minutes, I cut a circle (along with some plastic sample material) from a small piece of plywood included in the A5 kit.

Engraving an image on a piece of wood is a bit difficult. Sculpting is easy to pick up, but sculpting something correctly takes practice and experimentation. However, after a few bad and burnt sculpts, I managed to get a clean result.

The trick is to consult the materials database built into LaserGRBL. It has a section on Atomstack A5 which recommends setting the laser power to 28% for wood. Using this value with constant power instead of dynamic power produces beautiful results. Also, it is important to focus the laser by moving the head up and down.

I highly recommend doing all of this in a well-ventilated room, or preferably outside (as I did). Laser engraving works by burning the material, thus producing various toxic concentrations of fumes that you don't want to inhale. Also, wear goggles!

The Atomstack A5 laser engraver comes as a complete kit, including tools, green goggles, and even some sample material for practice. Assembling the kit is easy and, when done correctly, results in a solid, sturdy tool with smooth sliding X and Y axes and a stable head.

We also recommend more powerful lasers: atomstack a10 pro , atomstack s10 pro , atomstack s20 pro

Have you been looking for a laser engraver cutter but don't know where to start? You've probably seen a lot of different information and opinions that vary widely, so it's perfectly understandable if you're confused. There are a few key factors you need to consider before buying. In this article, we'll outline these factors so you can make an informed decision when shopping for a laser cutter that suits your needs.

Laser cutter: how will you use it?

The first thing you have to do is figure out what you want to do with your laser cutter and engraver. You probably already know what you want to do with a laser cutter, or a specific workflow that could benefit from it, but there are a few things you should know and consider first.

Laser Cutter: What Materials Will You Use?

You need to consider all the materials you want to use inside your laser cutter. Some materials work with one type of laser cutter, but may not work with other types of laser cutters. So gather a list of all the materials you want to use so you can be sure that the atomstack laser cutter you get will work with them.

Fiber lasers will be the best choice for metal laser cutting machines. These are more specialized machines, so there will be more restrictions on what you can do. These lasers will not engrave or cut what a CO2 laser can cut, any more than a CO2 laser can cut or engrave metal. If you want to engrave metal, a 20W or 50W galvo fiber will work well. The power you need will depend on how deep you want to carve.

If you're looking for an industrial-grade laser cutter for metal, you can get something like a kilowatt flat fiber that cuts metal like butter. Atomstack a10 pro lasers are only the size of a large truck, and they do cost more, but they can provide a decent return on investment (ROI).

Another popular technique is the UV laser. These lasers won't really cut any material, but they can mark almost any material you have. These look like fiber galvanometers at first glance, but they are significantly faster and capable of marking very fine details. UV lasers are ideal for marking, but keep in mind that they cannot cut most materials or make deeper engravings.

You need to check exactly what you want to do with the atomstack a5 pro laser cutter and understand the dimensions you need to fit in and consider the space you have available to install the laser system. The P-Series starts with a 20"x12" workspace and goes all the way up to 48"x36". These lasers also feature front and rear access doors that allow you to engrave longer materials. So if you have something long but not too tall, you can still use one of these units.

As individuals and small companies now have access to the latest technology, the laser cutting business has a promising future. Atomstack s20 pro Laser cutters were previously only available as large industrial tools to etch, engrave or cut a variety of materials. However, in recent years, the demand for small laser cutters that fit in your home has increased.

Low cost

As a start-up business, the initial cost of setting up a laser cutting business is low compared to many other businesses. The market isn't saturated yet, so there's a lot of demand, and once you carve out a niche for yourself, you should easily gain customers.

As with any industry, success depends on hard work and careful planning — but it's a lot easier when you choose a smart, relevant industry. Laser cutting businesses also compete with the 3D printing industry, but it is easier, more affordable and just as accurate.

No previous experience required

If you're a creative type, you probably make your own products and designs from scratch. That said, you don't need an artistic bone in your body to start a laser cutting business. You can create stylish items entirely by software and prefab designs. For the lowest start-up cost, you can just focus on sculpting existing objects for commercial or personal use.

Adaptable

The benefit of running a laser engraving, cutting and etching business is the ease of adapting to changing trends and evolving markets.

Laser Cutting and Sustainability

If starting your own laser cutting company doesn't sound tempting enough, there's a good chance it's taking advantage of the fastest-growing consumer trend: sustainability. When you communicate your commitment to reducing waste and protecting the environment through content marketing, you automatically align with the ethics of many modern consumers.

People who run a business from home have a great starting point explaining how they are protecting the environment. Your carbon footprint is already far lower than anyone doing business in an office.

Capturing data that reflects your low impact on the environment and usage is your marketing strategy. You can even etch reusable metal coffee mugs, custom reusable straws or any other eco-friendly product that is in high demand right now.

As a small business owner, you have the unique ability to communicate your brand's value to buyers. When customers are ethically aligned with a company, they are more likely to make an initial purchase and continue to buy.

Excellent material for laser cutting and engraving

Acrylic Fiber:

It is one of the best materials if you are running a laser cutting business. Laser cutting leaves a flawless finish and polished edges. Some plastics that you might think would react the same as acrylic (like Lexan) are dangerous. That's why you can never rely on guesswork to know which materials are suitable for a laser cutter - it's not always obvious.

Hardwood:

Atomstack lasers cut cherry, mahogany and other hardwoods well.

Leather:

Lasers love leather. Manual cutting usually takes hours and can be done in minutes using a laser. Be careful; it stinks! Leather is a great option if you are considering starting a quality laser cutting business. We'll discuss the best industries in more detail later.

Paper:

Card stock and paper cut quickly and have a good finish. Greeting cards or gift wrap made from recycled paper is a great idea for a laser cutting business.

Cardboard:

It does cut, but it's also a fire hazard, so never leave the laser cutter unattended while cutting cardboard.

Many types of wood: Most types of wood are suitable for laser cutters. However, you should avoid resinous or oily woods as they can burn.